Where others see waste, we see raw materials

Even the most modern production processes generate some degree of waste. That’s why waste management is seen as an environmental protection issue at edding, forming part of the edding value chain. At edding, waste products are seen as valuable raw materials.

In a closed-loop injection-moulding process, any sprue (leftover plastic) is returned immediately to the production process. Reuse of other plastic residues is also optimised.

In total, since 2015 83% of the plastic parts of the permanent, whiteboard and flipchart markers in the edding EcoLine range have been made up of post-consumer material, a recyclate, which is derived from “waste after usage”. This is plastic waste that comes from collected and returned, disused plastic components of all different types. Recyclate is produced following a multi-stage treatment process and can be used for the production of new products, including edding markers.

In total, 90% of the plastic parts of the edding EcoLine permanent, whiteboard and flipchart markers are made up of recycled material (83% post-consumer material and 7% pre-consumer material).

When it comes to plastics, packaging and inks, it goes without saying that we also separate and recycle waste, reuse as much as we can and dispose of it properly. But we don’t just think about recycling in production. Rubbish in our offices is also carefully separated and properly disposed of.

Responsible innovation

Our “Research and Development” (R&D) team is responsible for the initial and ongoing development of edding’s products, as well as for the necessary tests which all of our products undergo prior to series production. Among other things, products are tested for durability, storage, light resistance and writing.

Little by little, we are seeking to replace the conventional plastic material used in our standard products with secondary raw materials, where this is possible in products or product components.

We are specifically working on replacing the primary materials used in the manufacture of refill bottles. Key sustainability issues do not just affect the plastic components of our products, but more specifically the inks, where there are particular requirements in terms of quality. The inks need to work on a wide range of surfaces, have high brilliance of colour, be permanent or wipeable – and all of this with as few substances as possible, whilst being non-toxic. The solvents used are predominantly water (approx. 41%) and alcohol (approx. 36%). The remaining 23% or so of solvents are used for speciality inks and vary depending on customer requirements, or requirements concerning durability and the application surface.

Post-consumer recycling

For edding’s EcoLine products, we already make use of sustainable raw materials in the form of bioplastics and recycled materials. We have gained valuable experience in the use of these substances during the development of these products. This provides a sound basis for a gradual expansion in the use of alternative materials, especially post-consumer recycled materials.

At edding, it’s traditional to refill

Refill, not landfill!

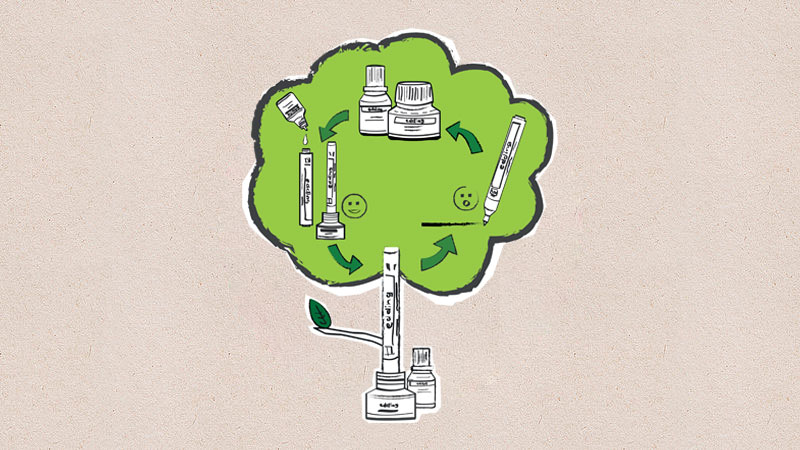

Refilling is a tradition at edding, not just a passing trend; edding has been selling refillable products for almost as long as it’s been in business. Currently, around 70% of our products are refillable; these include our permanent, whiteboard and flipchart markers. Furthermore, our highlighters, brilliant paper markers and a range of other edding writing implements can also be refilled.

Thanks to our refill systems, you can extend the life of a whole host of edding markers with total ease. Not only is this a great way of helping to reduce waste, it also saves on plastic used in the manufacturing of new markers. Oh, and it’s also easier on your wallet!

Conserve resources

The more frequently markers are refilled, the fewer the number of new markers that need to be made. And the fewer the number of new markers made, the more we can reduce the volume of new materials (such as plastic) used in our production processes. Therefore, refilling helps us to consume fewer resources, at a time when these are more precious than ever. Of course, our aluminium markers are also refillable, ensuring that we also use less of this raw material in the production of new markers. And if the tip of a marker loses its effectiveness over time, for many marker models this can often also be replaced with total ease.

Make mountains of waste a thing of the past

Extending the life of markers by refilling helps to reduce waste significantly. Even the supposedly small markers we dispose of once they’re empty can still add up to a not-so-small mountain of rubbish – one that’s mainly made of plastic. Our refill systems allow us to avoid this problem as much as possible. And if it gets to the point when your marker really can’t be used any longer, pop it in a return box and send it back to us. We’ll then recycle it, with 73% of the recovered plastic granulate being used in new products.

One bottle goes a long way

To a point! You can use each refill bottle up to 15 times. The precise number of refills per bottle will depend on your circumstances and your personal preferences. Unfortunately, there’s no rule of thumb when it comes to the perfect refill volume. The problem here is that the feeling of “writing on empty” is highly subjective. One user may notice a drop in writing performance and refill immediately, while another may feel the same pen is still “serviceable”, causing them to refill at completely different times.

One for all

Well, almost all! Our refill systems offer maximum flexibility. That’s because one bottle can be used to refill all kinds of edding marker within a given product range. Whether it be a bullet or chisel tip, fine or broad, almost all models can be revived using the same bottle thanks to our universal inks. This flexibility is also really handy because it means you don’t need to invest in a collection of different refill systems.

Clean and simple

Whether you opt for our capillary refill system or choose our drop dispenser, it’s quick and easy to refill our markers. And mess-free, too.

Great for your wallet too

Finally, refills aren’t just good for the environment; they’re also great for your wallet! With a refill system, you can avoid buying new markers (or buy fewer of them), benefiting the environment as well as your bank balance.

The edding refill systems

Why are there two different systems?

Different refill mechanisms are needed depending on the design of each marker. Markers with screw-on mouthpieces can usually be refilled using either system. Other markers must be refilled using the capillary system. Ultimately, your choice of system will often come down to personal preference.

The capillary system

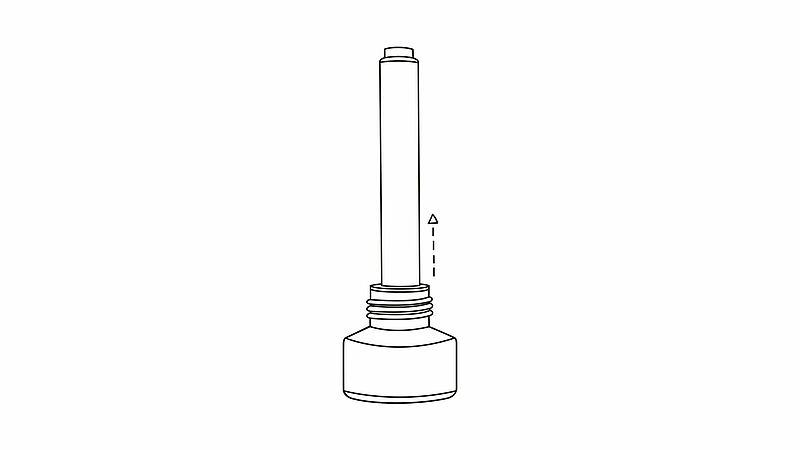

If you’re using the capillary system, simply stand the marker tip-down in the refill ink bottle for at least an hour, ideally overnight. The marker will refill automatically and can then be used again.

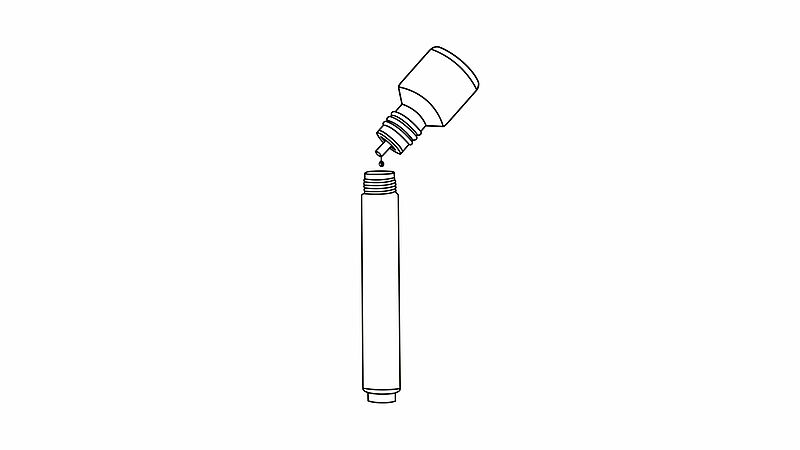

The drop system

The drop system is especially designed for fast refills. Simply unscrew the marker’s mouthpiece and dispense drops of the refill ink into the open barrel with the pipette provided. Depending on how empty the marker is, you’ll usually need 1–2 ml (approx. 50–100 drops) of ink to refill it. For thicker models, you may need around 4–6 ml (approx. 200–300 drops). You can use the pen again as soon as you’ve replaced the mouthpiece. Quick as a flash!

Keeping it going with every refill – step by step:

- Unscrew the marker’s mouthpiece in order to use the drop dispenser system OR, to use the capillary system, remove the cap and stand the marker tip-down in the refill bottle.

- Dispense drops of ink into the marker barrel OR wait until the product has filled up from the capillary refill bottle.

- Screw the mouthpiece of the refilled marker back on OR remove the refilled marker from the refill bottle and replace the cap.

- Carry on writing!

edding EcoLine

Awarded for excellence!

For the fourth time in a row the edding EcoLine series has been honoured as a "green brand" by the international brand marketing organisation GREEN BRANDS in March 2021. Our Green Brand seal of quality now already bears three stars. The award recognises ecologically sustainable brands that reflect people’s increasing awareness of the need to be more sustainable, protect the environment and lead a healthy lifestyle. Green Brands recognises a brand’s commitment to climate protection, sustainability and environmental responsibility.

The edding 24 EcoLine highlighter

Anyone trying to find new ways of looking after the environment will often find that the solutions come from nature itself. Here at edding, we’ve worked hard to develop the most eco-friendly product in its category. The result is our edding 24 EcoLine highlighter series, made predominantly from renewable resources such as sugar cane. We’ve been rewarded for our efforts as we have now been awarded the Blue Angel ecolabel – a first for highlighters everywhere!

edding 24 EcoLine highlighter

- Highlighter for the luminous marking and highlighting of text passages and notes on almost all paper surfaces

- Awarded the Blue Angel eco-label

- At least 90% of the cap and barrel are made from renewable resources

edding 22 EcoLine permanent marker

- Permanent marker for marking and labelling almost all materials, e.g. paper, cardboard, metal, plastic and glass

- At least 90% of the total plastic used in the marker is made from recycled material (83% post-consumer)

- ClimatePartner certified product. Information on offsetting the greenhouse gas emissions of the EcoLine can be found here: www.ClimatePartner.com/13742-1910-1001

edding 32 EcoLine flipchart marker

- Flipchart marker specially designed for writing and marking on flipchart paper, presentation paper / cards and other paper sheets

- At least 90% of the total plastic used in the marker is made from recycled material (83% post-consumer)

- ClimatePartner certified product. Information on offsetting the greenhouse gas emissions of the EcoLine can be found here: www.ClimatePartner.com/13742-1910-1001

edding 28 EcoLine whiteboard marker

- Whiteboard marker for writing and marking on whiteboards and also suitable for flipcharts

- At least 90% of the total plastic used in the marker is made from recycled material (83% post-consumer)

- ClimatePartner certified product. Information on offsetting the greenhouse gas emissions of the EcoLine can be found here: www.ClimatePartner.com/13742-1910-1001