How cleanrooms minimise contamination

Special air flow

These special rooms minimise the amount of particles per cubic metre of air by using special filtration and airflow systems. They are designed to take the entirety of the environment’s airflow into account and change the air in the room frequently. The cleanroom classification determines which type of filtration (HEPA or ULPA) and airflow systems (laminar or turbulent) are appropriate. A considerable distinction in the two filter types comes down to the size of the particles that can be removed: HEPA filters can eliminate up to 99.97% of pollutants as small as 0.4 microns, and ULPA filters can eliminate 99.99% of pollutants as small as 0.12 microns.

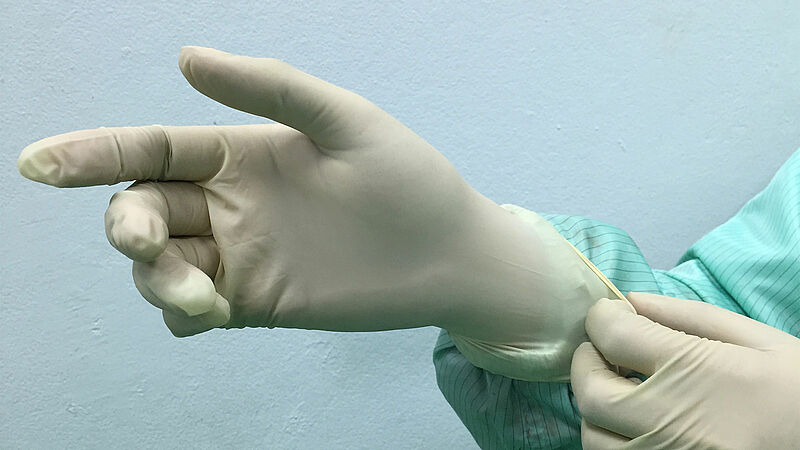

Cleanroom environment attire

The people working in these rooms represent the greatest potential source of contamination. Shed skin, dandruff, sweat, and dirt brought in from outside are all possible contaminants. Special garment systems are required that follow specific guidelines, and do not release fibres or other particles themselves. These garments act as a particle filter and barrier between the person working and the cleanroom environment.

Air showers

Depending on the cleanroom classification, air showers may be used between the gowning area and the room itself. These enclosed chambers use high pressured HEPA/ULPA-filtered air to remove contaminants (like dust, lint, and dirt) from the person and their garment system before they enter the room.

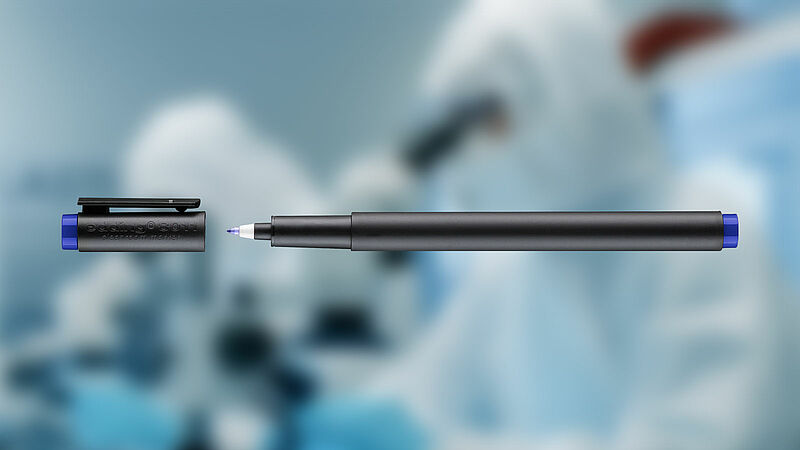

Specialised tools and writing materials

Most of the tools we use every day – like paper, writing instruments, and tape – produce dust, can harbour microbes, and can serve as conductors. Specially-certified tools and writing materials that minimise particle release are required for use in cleanroom environments.

Cleanroom-appropriate furniture and cleaning supplies

All of the furniture inside should be easy to clean, impervious to microbes, and should release as few particles as possible. The cleaning supplies used are likewise specially designed to reduce the amount of particulate matter released.

Exploring the world’s largest cleanroom

These rooms are used in plenty of industries, from micro-technology to aerospace engineering. The High Bay Cleanroom at NASA’s Goddard Space Flight Centre is the world’s largest, however, and is where the sensitive instruments for the Hubble Space Telescope are assembled, housed, and tested. A speck of dust or fingerprint could result in a failed mission, so workers must follow strict cleanroom guidelines. They must wear a specialised garment system and pass through a number of chambers that rid them of as many particles as possible: one with a sticky floor to remove dirt from shoes, as well as an air shower. The High Bay Cleanroom also uses an entire wall of special high-efficiency particulate air (HEPA) filters, which circulate one million cubic feet of air every minute.

The High Bay Cleanroom has a classification of ISO-7, meaning no more than 352,000 airborne particles sized 0.5 µm or larger can be in a cubic metre of air (human hair is 75-100 µm in diameter). High Bay Cleanroom’s excellent filtration systems and careful guidelines all work to ensure that missions to service the Hubble Space Telescope are a success.

More interesting topics to read about

Which products are right for which cleanroom classes?

The equipment used in these rooms is an important source of contamination and using normal everyday items can spell disaster. Different classes require different levels of strictness, so it is important to know which products are allowed.

edding 8011 cleanroom marker

This marker is certified for use in ISO-2 and 3 class cleanrooms. With its metal and label-free design and 0.6mm round nib, the edding 8011 releases a minimal particulate matter such as dust, is water and smudge-proof, and comes with a convenient cap with clip.