Useful cleanroom supplies for different ISO classes

Cleanroom paper and notebooks

Taking notes should always be done using cleanroom supplies designed for that purpose. Cleanroom paper is non-shedding, and has been coated to seal individual fibres and minimise the release of particles and the absorption of microbes. Likewise, cleanroom notebooks make use of this specialised paper and are bound using a poly spiral.

Cleanroom markers

While normal writing instruments can release particles of dust, cleanroom markers and pens are designed so that taking notes doesn’t result in unnecessary contamination. Cleanroom markers use low-dust fibre or non-fibre nibs, and use ink that reduces the risk of ionic contamination.

Cleanroom tape

In cleanrooms, tape serves many functions, like marking the floor and colour coding tools. The properties of cleanroom tape allow for the creation of strong bonds without leaving any residue, and it is often laminated so it remains particle-free. It can also include properties that make it easy to tear, anti-static, non-outgassing, and durable.

Cleanroom supplies for cleaning

Cleaning a cleanroom rids its surfaces of as many particulates as possible. Vacuum cleaners should therefore be equipped with filtration systems. Mops, used on walls and ceilings as well as floors, shouldn’t distribute fibres. Specially woven cleanroom wipes and sponges are essential for picking up and disposing of contaminants.

Garment systems for cleanrooms

Depending on the class of a cleanroom, the appropriate apparel will be more or less extensive. Required attire may range from a lab coat without pockets and a hair net to garment systems that fully cover personnel with oversleeves, frocks, hair and beard nets and hoods, gloves taped securely, face masks, and shoe covers.

How is a cleanroom test conducted?

Once a cleanroom has been built, it is important for it to be tested periodically (annually or semi-annually) to ensure that it is being maintained to the standards of its ISO 14644-1 class. Cleanroom tests determine whether the air flow design and filtration systems work properly so that the amount of airborne particles do not exceed the specified maximum.

Cleanroom tests focus extensively on making sure the airflow system functions as it should. Not only should the air flowing into and out of the cleanroom be adequate, but it should also flow properly inside the cleanroom itself and from area to area.

HEPA and ULPA filters are also tested for leaks, and any leaks found are checked to make sure that unfiltered air is not entering the cleanroom.

Finally, the concentration of airborne particles is measured using particle counters that use a light scattering principle to measure both the size and amount of particles per cubic metre.

Depending on the industry requirements of a cleanroom, more tests will be conducted to ensure that it is up to standard, such as tests of the cleanroom’s temperature and humidity, as well as vibration, sound and light levels. If products are used in the specific environment they need to be tested as well. For example, edding’s 8011 cleanroom marker underwent testing on its outgassing and surface cleanability by an external institute. Regarding air cleanliness, the black colour was awarded class 2, and blue received class 3 according to the ISO 14644-1 standard. This kind of test also needs to be conducted for other cleanroom products.

More interesting topics to read about

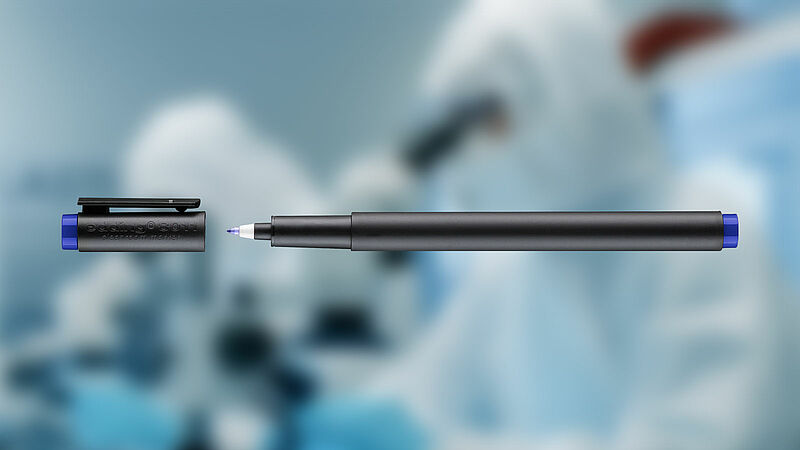

edding 8011 cleanroom marker

This marker is certified for use in ISO-2 and 3 class cleanrooms. With its metal and label-free design and 0.6mm round nib, the edding 8011 releases a minimal particulate matter such as dust, is water and smudge-proof, and comes with a convenient cap with clip.

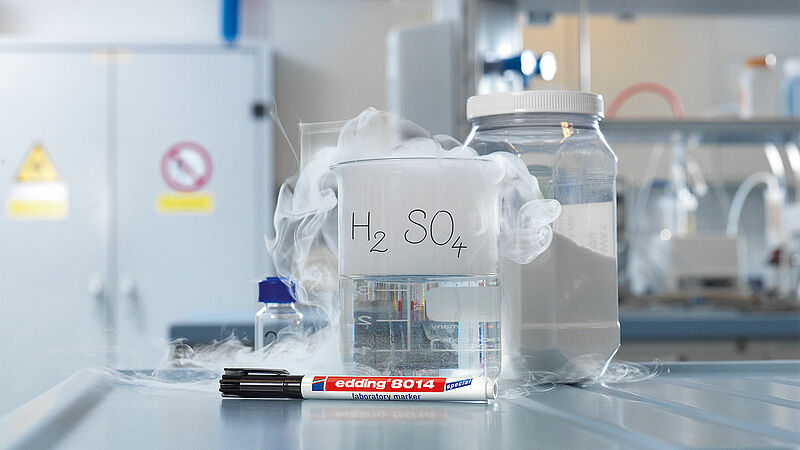

edding 8014 laboratory marker

Certified by the German Association for Technical Inspection (TÜV), this laboratory marker can withstand extreme temperatures ranging from -183°C to +500°C, is waterproof and lightfast, making it a reliable tool for use in laboratory environments.